PRINTING RESOURCES

There are many printers and reproduction services available world-wide, in addition to some pieces you might generate on your office equipment. For large commercial runs, Chinese printers are the most cost effective as long as language issues do not create false production requirements. Online print companies offer the best prices for gang-printing by placing multiple jobs on the same plate, because the setup costs are shared. Local print companies are the best choice for custom runs and where quality control and special treatment are critical.

PRINTING METHODS AND TECHNOLOGIES

• Offset Printing: Transfers ink from plate to paper, good for large runs.

• Digital Printing: Plateless, ink direct to paper, best suited for short runs, limited paper choices.

• Large Format Printing: Ink sprayed onto substraights, for murals, banners, signage, vehicle wrap.

• Screen Printing: Ink forced through masked fabric, best for non-paper surfaces, metal, plastic, cotton.

• Color Copy Machines: Powdered toner fused to paper with Xerox™ technology.

CMYK OFFSET PRINTING

Offset printing uses combinations of four primary inks; Cyan, Magenta, Yellow and Black, capable of producing a spectrum of reflective, or subtractive, color, commonly referred to as CMYK. Artwork is color-separated into these four colors as line-art and printing-plates are made from the separations, hung on the press and registered for alignment. Solid swatches of each process color are shown below.

OFFSET PRINTING PRESSES

Presses are categorized by the number of color stations and width. The most common offset presses are capable of printing five or six plates at the same time. Since CMYK requires a minimum of four color stations, the additional fonts can be used for spot color and/or selective coating, which avoids the need to run jobs through another press at increased cost. There are one-color presses and some may have as many as ten color stations. The size of the press determines the limit for the maximum dimensions of the paper and the maximum printable area on the sheet, which must include some bleed for registration-marks, crop-marks, color-bars, and the paper-gripper on the press. Presses need to be calibrated, and the only global standard is established and maintained by Pantone™, which engineered the science of controlling ink formulas and the benchmark for what is referred to as putting down 100 percent of an ink. Not all printers follow Pantone guidelines, which means their presses will not achieve expected results by putting down too much, or not enough ink.

RGB COLOR ON COMPUTERS

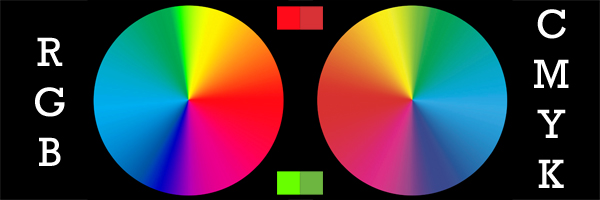

Print files prepared digitally on computer are displayed by mixing red, green and blue light with an additive system known as RBG color as seen on a monitor display. RGB is also used for photographic methods in digital cameras, positive and negative films. RGB and CMYK are two completely different methods of working with color. The visual spectrum of color in the RGB gamut that mimics natural light is much larger than the CMYK gamut. Print files should be prepared in CMYK file mode limited to a printable pallet. Some printers accept RGB images, but in the end, software will convert RGB color values into CMYK formulas. Since bright RGB colors have no equivalent in CMYK, gross color errors can occur in the translation. Please note that it is not possible to print RGB colors on a reflective surface with ink!

| This image shows a visual comparison between the RGB and CMYK spectrum of full-strength-color, tints and shades not included. Squares show simultaneous contrast between the most saturated red and lime-green for both gamuts. |

PROCESS COLOR

With only four primary colors in the CMYK process, it is only possible to print seven solid colors on a four-color press: cyan, magenta, yellow, red (100%M+100%Y), green (100%C+100%Y), blue-violet (100%C+100%M), and black as solids. All other process-colors are created by over-printing percentages of the CMYK as transparent dots to mix a speckled color on the paper. Secondary colors like oranges and greens are typically weak and lack saturation in process printing.

| Enlargement of orange created by printing 100 percent yellow over-printed with 50 percent magenta dots. |

SPOT COLOR

Spot colors are used when a uniformly solid color is desired. It means that 100 percent of the ink is printed on the paper. Before four-color-process printing was possible, colors were printed as solids, limiting designs to a basic feeling, generally without subtle shifts of color. Companies often have a corporate color scheme and will print additional spot color so their brand-color looks as rich and consistent as possible in print. Spot colors are not available on ganged-print-runs, so the use of spot color requires a custom print job.

| Color comparison of the same inks printed on uncoated stock in the upper row and coated stock below. |

PRINTING ON PAPER STOCK

There are a huge number of varieties of paper available which represent different textures, weights and colors, however, general full-color printing is done on papers that are white. The brighter the paper, the most vibrant the printed colors will look on it. To me brighter is always better because it creates a wide latitude of the most intense color. Tasty, muted color combinations can be created printing on colored papers, yet the use of white is unavailable. Coated papers are most commonly used in process-printing because they are less absorbent and make inks look juicy. Calcium carbonate is most often used for coating papers used in commercial printing to impart certain qualities to the paper, including weight, surface gloss, smoothness, and ink absorbency. In comparison, uncoated papers are more absorbent and produce a matte look with colors that are less vibrant. There are also many new recycled papers on the market to choose from.

APPLIED FINISH COATINGS

There three basic coating options available commercially: UV Gloss for a high gloss finish, Aqueous Gloss for a satin finish, and Aqueous Matte for a flat finish.

QUALITY VARIABLES IN PROCESS PRINTING

There are many variables that affect the quality of printing results. A good printer will take care to make sure the shop and equipment is maintained in consistent fashion. Typical variables include: condition of the printing equipment, press calibration (ink density), printing plates, ink to water ratio, press color controls, press operator, humidity, outdated color books, and viewing conditions.

SELECTING A PRINTER

Print companies are not created equal and their capabilities vary widely. When shopping for a printer, ask for samples of their work to include coating and color swatches. It is important to see how accurately their press system is calibrated for duplicating consistent color, as established by Pantone™, for custom inks and four-color-process. I have found a several gang-printers that only use coarse line screens, some in a rosette shape, that produce unacceptable results, so be careful, particularly on large print jobs. When working with a printer for the first time, I would suggest trying a small job to keep risk low.

PRINTER SUPPLIED DESIGN TEMPLATES

Each printer has a certain set of equipment and workflow. Many of them require print files to be formatted in a specific manner and offer free templates for download to avoid dealing with file format variables. Once the design is executed, files are uploaded to the printer's server as PDF documents for pre-press review. As some printers are sticklers on this point, it will save energy to create designs after finding out their requirements.

PRE PRESS PROOF SHEETS

The press-press department verified that documents and associated images are properly prepared. If there are technical problems, they will suggest changes and ask for new corrected files. If the files are press-worthy, they will generate a proof for one's approval. The designer can ask for a PDF proof online, or hard copy proof via the mail that takes more time. Once the proof is approved, the job is sent into production.

– – Mark Smollin |